×

Horizon Digital Print invest in a third Esko Kongsberg table adding the C44 Sign Production machine to their existing Esko portfolio of tables, upgrading the existing XP44 to IPC3 frontend software and adding in an additional seat of Artios Cad completes the investment.

With over 80 employees and over 30 years experience Horizon Digital Print established in 1986 continue to invest in industry-leading machinery.

We would like to thank Derek Gillen and his team for putting his trust in GPMI once again, and we look forward to many more years as a supplier.

Agfa lines up its market broadside

Since the launch of its new generation of :Jeti wide-format inkjet printing technology, Agfa Graphics has been working hard to capitalise on its intensive spending on technology research and development—and it seems its efforts are now paying off.

The Agfa :Jeti Mira was launched as part of an ambitious programme of product portfolio expansion by the graphic arts giant

A steady number of sales across the UK and Europe have seen the printing giant extend its market share in the commercial print and sign-making sectors, with a key strength being its Thin Ink Layer Technology, which makes running its machines very economical.

Print Monthly spoke to Willy Van Dromme, marketing manager, sign and display for Agfa Graphics, and asked him to explain what is driving its progress: “Our approach has been to develop matched systems and bring them to market.

“We manufacture and develop our own ink, our own systems, and of course the software that drives the inkjet heads. We believe that by controlling the hardware, the ink, and the application know-how, we can offer best-in-class image quality, consistency, and colour reproduction.

We manufacture and develop our own ink, our own systems, and of course the software that drives the inkjet heads”

“The other important factor is that two years ago we started to develop a new line of products that are based on what we call a ‘common platform design’.

“So, we spent a significant amount of research and development money on building a high-end wide-format inkjet hybrid system, that enables us now to develop new technology from this base with a much shorter time to market.

“The final element is that there is a non-stop focus on quality and consistency in our manufacturing process, so that our products deliver highly-reliable and effective performance.”

New Mimaki UJF MkII range to be launched in March

Mimaki’s exclusive UK and Irish distributor, Hybrid Services, will launch new small format LED UV and production direct-to-textile inkjet printers at this year’s Sign & Digital UK exhibition in Birmingham. In addition to supporting its network of resellers who are also exhibiting at the show, the Hybrid stand will feature its hugely popular range of solvent printers and printer/cutters, flatbed and grand format UV printers.

The recently announced Mimaki UJF MkII range of A3 and A2 sized flatbed printers offer next-generation direct to object print capabilities and follow in the footsteps of the original UJF range that rapidly became the de facto small format solution for branding, promotional items, manufacturing components and bespoke gifts.

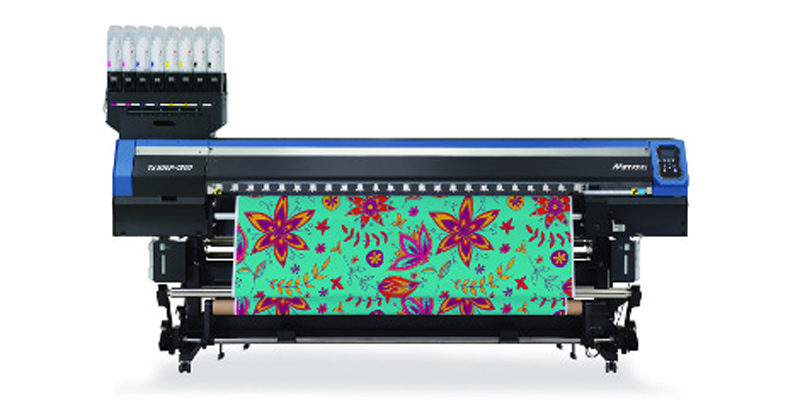

Mimaki’s new Tx300P-1800 wide format textile printer sees its UK debut at the show and offers a broad range of fabric printing opportunities thanks to its flexible ink configuration options. As capable of producing fashion or furnishings as it is soft signage, the brand new 1.8m printer’s ability to run multiple ink sets, opens up a vast array of applications on manmade or natural fabrics.

John de la Roche, National Sales Manager at Hybrid, states the company’s intentions during the show: “Sign & Digital UK is a key date in Hybrid’s diary. It’s the ideal opportunity for visitors to gain a snapshot of our industry and for us to meet with customers old and new. We’re returning once again in 2017 with impressive new products that join Mimaki’s award-winning line-up of solvent, UV and textile printers. Most importantly, we’re looking forward to showing visitors how Mimaki technology can really benefit their business.”

In addition to the exciting product launches, the Hybrid stand will also feature a broad range of Mimaki solvent printers and integrated printer/cutters, available in a variety of sizes from 75cm up to 1.6m print widths.

“Mimaki’s multi-award winning sign and graphics line-up enjoys a strong reputation within print and display companies the world over,” continues de la Roche. “We’re confident visitors will be inspired by the many creative opportunities these machines offer and look forward to helping them build their businesses with Mimaki’s proven line-up.”

Visitors will also benefit from seeing two of Mimaki’s largest products on display – the hugely successful UJV55-320 grand format LED UV roll fed printer that has taken the backlit sector by storm since its release a year ago and the all-conquering JFX200 flatbed LED UV printer.

“Mimaki has a long history of delivering solutions that hit the requirements of the UK and Irish graphics market and these two UV printers are a perfect example,” adds de la Roche.

Hybrid’s stand can be found directly inside the entrance to the show, which is located at the NEC in Birmingham from March 28th – 30th 2017.

Commercial Print Announcement

We are pleased to announce that Niall Fitzgerald started with us today as Business Development manager for commercial print in RoI. Niall will be responsible for growing the commercial print business in the market through identifying opportunities with existing customers and exploiting opportunities with other commercial printers outside our customer base. Niall will be responsible for the outside CP team and packaging .

This is an exciting time for GPMI commercial print and we welcome Niall on board.

European Digital Press Association rewards Jeti Mira from Agfa Graphics

Today, the winners of the EDP Awards 2016 were announced at drupa 2016. Agfa Graphics’ Jeti Mira was recognized by EDPA for its excellence. The Jeti Tauro was nominated as well.

Mortsel, Belgium – June 1, 2016

The European Digital Press Association grants the EDP Awards to the best products of the year introduced in the European market. It reviews quality, but also aspects such as value to the user, support and service.

Agfa Graphics is proud to have been rewarded with this quality and innovation mark for the Jeti Mira in the category ‘Best wide format flatbed/hybrid printer up to 250 m²/h’. The Jeti Mira is a 6-color and white UV-inkjet true flatbed printing system featuring a moving gantry. It is one of Agfa Graphics’ newest UV-inkjet solutions, ideal for applications ranging from posters, signage, exhibit graphics and POP displays to niche applications such as DVDs, wood, art reproductions, personalized objects and more. Printing varnish or primer are options.

At drupa, the Jeti Mira is on display with the dockable roll-to-roll option offering a unique solution to print on a wide variety of both flexible and rigid media.

The Jeti Mira is driven by the Asanti workflow software (EDP Award winner in 2014), which takes control of the entire process, from prepress to production through finishing. Asanti’s file handling, color management and preflighting raise the efficiency of the complete system with fewer errors and reduced time loss. Asanti is completed by Asanti StoreFront, Agfa Graphics’ web-to-print solution that enables management of online stores and automatic processing of print orders.

About the European Digital Press Association and the EDP awards

The European Digital Press Association (EDP) acts as a recognised industry forum and groups publishers of leading European magazines who are all devoted to digital printing and associated products. Combined, these magazines cover 14 European countries and address more than 1 million professional readers.

The Association grants the EDP Awards to the best products of the year introduced in the European market to acknowledge the value of the research and development tasks of the industry. A technical committee made up of independent consultants, editors, engineers and other related professionals, has been assigned the task to check the products launched in Europe during the year.

Evaluation is based on innovation. The EDP Technical Committee judges the products on the value of the new technical abilities they offer. This can be innovation in the technology that improves speed, quality, usability and functionality or reduces environmental footprint as well as cost to the user.

About Agfa

The Agfa-Gevaert Group is one of the world’s leading companies in imaging and information technology. Agfa develops, manufactures and markets analogue and digital systems for the printing industry (Agfa Graphics), for the healthcare sector (Agfa Healthcare), and for specific industrial applications (Agfa Specialty Products). Agfa is headquartered in Mortsel, Belgium. The company is present in 40 countries and has agents in another 100 countries around the globe. The Agfa-Gevaert Group achieved a turnover of 2,646 million euros in 2016.

About Agfa Graphics

Agfa Graphics offers integrated prepress solutions to the commercial printing industry, the newspaper printing and publishing industry and the sign and display, decoration and industrial inkjet printing industry. These solutions comprise consumables, hardware, software and services for production workflow, project and process management, cloud software and image processing.

Agfa Graphics is a worldwide leader with its computer-to-film, computer-to-plate, digital proofing and security solutions for commercial and packaging printers.

For newspaper markets Agfa Graphics is leading supplier of automation for printed and mobile publishing workflows.

Agfa Graphics has also developed a prominent position in the new segments of industrial inkjet. It offers a wide range of inkjet presses and a complete assortment of high-quality inks.

Contact:

Paul Adriaensen

Agfa Graphics Press Relations Manager

tel. ++32 (0)3/444.3940

e-mail: paul.adriaensen@agfa.com

Large Formats Review of the Mimaki JFX200

LFR’s Marc Burnett offers his opinion on the Mimaki JFX200 and details why he believes it is a UV flatbed printer that businesses cannot afford to ignore.

At this year’s Sign & Digital UK exhibition there were four Mimaki JFX200 printers being demonstrated on four different booths; three of those booths belonged to resellers who would have had to significantly increase their booth floor-space costs in order to showcase the Mimaki flatbed. They’ll have made that investment with confidence that the increased cost of demonstrating the printer will have been offset by leads and indeed sales.

The point I’m making is that the Mimaki JFX200 is a printer that is rapidly becoming the de facto standard for any sign and display print business looking to make a move into flatbed UV printing, and the resellers know it – they are all excited at the new business that they are winning with this latest Mimaki flatbed.

Mimaki is also rightly proud of the sales numbers across Europe, the Middle East and Africa. The company reports a steady growth in sales of the JFX200 UV flatbed since its launch date.

Currently Mimaki is selling more than 40 of its JFX200 printers every month, and these impressive sales numbers are still on the increase. Indeed the Mimaki JFX200 is, according to Mimaki Japan, now the world’s top selling UV flatbed printer. Undoubtedly it has to date been one of the most successful product launches in Mimaki history.

So what’s the fuss all about? Why is this flatbed printer creating such a buzz, and why is it being installed in these record-breaking and market-defining numbers?

First off, let’s give you a quick snapshot view of its capabilities: The Mimaki JFX200 UV LED flatbed printer is able to print 8′ x 4′ rigid boards up to a thickness of 50mm, at up to 1200 dots per inch with quality further augmented through variable dot printing down to a 4 picolitre drop size – and it does all this at a speed of up to 25 square metres an hour.

As well as the primary CMYK ink set, you’ll find zero-cost options for printing with white ink, clear ink (with a primer coming soon) and now a choice of LH100 hard inks, LUS150 flexible inks and most recently LUS200 fully flexible inks for thermo forming type applications.

The net result is a high quality, fast and versatile flatbed UV printer that performs well beyond its price point.

Here’s a more detailed look at why we think this outstanding printer should be on your shortlist, broken down for you in 3 key areas:

1. Capital Cost:

Today, if you buy a Mimaki JFX200 flatbed UV printer, you’ll get one for £59,995. That’s an incredible price, for a number of reasons.

Firstly this price falls way below the significant psychological barrier that exists when purchasing a UV flatbed – so far below it in fact, that the mind-set of the buyer is changed from thinking of it as an investment comparable to ‘buying a small house’ to instead comparing it to ‘buying a nice car’. That’s a big shift in the purchasing thought process.

Do you think that theoretical glass ceiling of product pricing doesn’t matter? I can assure you it does. And the veritable queue of buyers lining up to buy this affordable flatbed print powerhouse is all the proof you need. In pricing this printer, Mimaki has effectively created a whole new price point, a whole new customer base, and sales success has subsequently followed.

This price also sits the Mimaki in the midst of competing printers that simply, well, cannot actually compete that well.

To get like for like performance, comparable build quality, and the ability to print 8’ x 4’ boards rapidly and at high quality, you’d have to spend significantly more on any alternative.

To get like for like pricing, you’d need to be looking at a brand-name printer that has been throttled back in terms of its features, functionality and productivity – or you could of course take a gamble and try your luck with a cheap flatbed printer of questionable origin, more than questionable pedigree and the distinct possibility of all but non-existent after-sales support.

2. LED Lamps:

We’ve previously written a feature on the benefits of LED UV lamps – read it here to save us going over the same ground again – and the benefits, for the jobbing printer certainly, are significant.

In a nutshell you’ll get significantly longer lamp life – by a factor of multiples – when compared to mercury lamps.

With LED lamps you’ll get no realistic heat produced; LED lamps are cool in more than one sense and what this means in real terms is an ability to print to more substrates, including thin and sensitive materials.

You also benefit from Mimaki variable lamp intensity – beyond the simple On or Off of most mercury lamps – again meaning better tuning of cure performance to the specific substrate and ink partnership.

When talking about LED vs Mercury, warranty is also a factor, and a potential cost. A typical mercury lamp will have a lifespan of about 500 to 1000 hours, so if you’re busily printing you’ll be changing lamps every 3 to 6 months, or you’ll inevitably suffer from the inherent degradation of curing performance that comes as standard with a mercury lamp equipped printer.

The expected life of the Mimaki LED lamps is actually well in excess of 10,000 hours, with Mimaki reporting a potential upper operational ceiling of as much as 20,000 hours. That said, the actual warranty on the lamps is for 5,000 hours of printing – plenty enough to last your average sign & display print shop a good number of years.

3. Warranty and Credible UK based Support

Beyond the lamp issue, here in the UK you’ll be buying a Mimaki JFX200 with a full 2 year warranty as standard. That’s 2 years for you to recover your up-front capital costs before you even begin to consider the cost of your printers maintenance and upkeep. Indeed if your £59,995 Mimaki JFX200 has not paid for itself within that warranty period, well frankly, you’re probably in the wrong game.

From the end of year 2, you’ll be looking at an annual cost of just £4,995 for a warranty that also covers the printheads and again the lamps, even when the lamps have gone beyond their own 5,000 hour warranty.

The warranty is provided here in the UK by exclusive Mimaki UK & Ireland distributor Hybrid – with service provided by its own in-house Mimaki-trained engineering team.

Yeah but…

Of course there are counter arguments. One of them might be that bigger, faster and more expensive UV flatbed printers have lower ink costs. Personally, I think that’s perhaps an argument best saved for the time when you actually need a bigger, faster and more expensive UV flatbed, perhaps to meet the demand for higher print volumes from business that your Mimaki JFX200 might have won for you.

The bottom line?

In my opinion, today, right here right now, at this price point you simply cannot make a flatbed UV printer purchase without first taking a very close look at the Mimaki JFX200.

Think I’ve got it wrong? I’m here to be proven wrong, and I’m more than happy to listen to any counter-arguments, and indeed give you the platform of LFR to share your thinking. Get in touch.

New Mimaki TS300P-1800 launched at FESPA

Mimaki, a leading global manufacturer of wide-format inkjet printers and cutting plotters for the sign/graphics, textile/apparel and industrial markets, today announced the availability of the TS300P-1800 inkjet printer. This 1.8m wide roll-to-roll sublimation inkjet printer is a dedicated transfer paper printer, offering new levels of quality and productivity in digital textile printing.

The Mimaki TS300P-1800 will begin shipping in July 2015. Mimaki is located on Stand U5-T11 at the show, and will be featuring stylish mannequins clothed in vibrant textiles, printed on the TS300P-1800.

“With the textile market booming, Mimaki has placed even more emphasis on bringing innovative digital textile printing solutions to market,” said Mike Horsten, General Manager Marketing EMEA at Mimaki Europe, “and the result is the brand-new TS300P-1800 printer. Visitors to our stand will see real-world examples of printed textiles that bring to life the real potential of digital print for this market. We are very excited about the speed, quality and productivity that can be attained with the TS300P-1800 and are confident it will be enthusiastically received by fashion and other textile users.”

Technological features that anticipate everyday reality

The TS300P-1800 brings a number of new capabilities to textile printing, including:

- The ability to print on very lightweight transfer paper for lower running costs with a powerful vacuum feed platen that reduces cockling.

- High productivity at 115m2/h maximum print speed at 4 colour printing (62 m2/h with 6 colour printing)

- Four print heads with a total of 3,200 nozzles and up to 3 different drop sizes, automatically determined by ink type and print mode; accurate dot placement even with high head gap printing (adjustable from 2 to 7 mm).

- Continuous quality printing is assured with the automatic Nozzle Recovery System should a clogged nozzle occur that cannot be addressed by the printer’s automatic nozzle cleaning system.

- The newly developed sublimation transfer ink Sb410, available in bulk ink packs and an Uninterrupted Ink Supply System that ensures continuous printing even when unattended.

- External dryer that delivers up to 30% faster drying.

- Highly reliable unattended printing at up to 115m2/h for reduced labour costs.

- Exceptional colour management including colour replacement, accurate profile creation and fast file processing with the new Tx3Link RIP. The printer and RIP can be in different locations to facilitate more efficient system management and operation. The status of multiple printers can be monitored remotely from desktop or mobile devices. The Tx3Link RIP also enables accurate calculation of ink costs and print finish time as well as automatic nesting.

“This new printer brings so many innovations to the textile printing market that it is hard to summarize them all,” Horsten added. “We encourage FESPA attendees to stop by to see this outstanding product for themselves. We’re so confident about its quality we even dressed up the mannequins on our stand in Mimaki printed textile. Digital textile printing is taking over the textile retail market, starting with sporting apparel. Mimaki is ready to respond to the inevitable demand from the market with the brand-new TS300P-1800.”

Incredible result for leading Irish solutions provider

Well, from all accounts, it was some night of celebration for Ken Kavanagh and Derek Gillen, joint MD’s of Dublin based Horizon Digital Print Solutions, as they carried off the ‘Gold’ at the international FESPA Awards 2014.

Horizon’s in-house Halloween Promotion and the Heineken Interactive Kick Game won joint gold for Best Integrated Print Campaign at the exhibition.

The Irish company, which is a leading supplier of Point of Sale, Outdoor Advertising, and Interactive Digital Campaigns, has over 30 years experience in the industry. With 60 employees, two purpose built facilities, and continuous investment in industry-leading machinery, its clients include blue chip brands such as Tesco, Heineken, and Cadburys.

FESPA is a global federation of 37 national associations for the screen printing, digital printing and textile printing community. Not only was Horizon there for the awards ceremony, it also wanted to see what the latest technology game changes were in print, and decide what’s next to buy.

Pictured are Horizon MD’s L-R Ken Kavanagh and Derek Gillen with the winning trophy

HP Latex LX800 Open House

Reprocentre plan to run a open house in our Reprocentre Dublin showroom on the 11th,12th 18th & 19th May…showcasing for the first time in Ireland the HP Latex LX800 3.2m wide printer.